In manufacturing, efficiency is paramount. Every bottleneck, every pause, and every material handling challenge can impact your bottom line. For industries working with large volumes of raw materials supplied in coils – think metal strips, wire, or other flexible materials – the seemingly simple act of uncoiling can become a significant hurdle. This is where the unsung heroes of the production line, decoilers, come into play.

The Challenge of Coiled Materials

Working with coiled materials presents unique challenges:

- Weight and Bulk: Coils can be incredibly heavy and cumbersome, requiring specialized equipment for handling.

- Inconsistent Feeding: Maintaining a smooth, consistent feed rate is crucial for continuous production, but variations in coil tension and unwinding speed can lead to disruptions.

- Material Integrity: Improper handling can lead to material damage, waste, and quality issues.

- Downtime: Manual handling or inefficient unwinding processes can cause frequent stops, leading to costly downtime.

What is a Decoiler? More Than Just an Unwinder

At its core, a decoiler is a machine designed to efficiently unspool coiled materials, preparing them for the next stage of the manufacturing process. However, modern decoilers, especially those integrated into automated systems, are far more sophisticated. They are engineered to:

- Balance Speeds: Effectively balance varying reel-off and draw-off speeds to ensure a constant and controlled material flow to downstream machinery. This is critical for high-speed, continuous operations.

- Handle Heavy Loads: Built with robust construction, they can manage significant coil weights, often directly from pallets, eliminating the need for additional handling equipment.

- Prevent Issues: Features like strap tension control and strap end detection help prevent tangling, material damage, and unexpected halts.

VIAL Automation: Your Partner in Coiled Material Handling with Standard & Custom Solutions

At VIAL Automation, we understand that efficient material feeding is the foundation of a productive manufacturing line. Our solutions are developed as standard components for automated and semi-automated manufacturing applications, ensuring reliability and high performance.

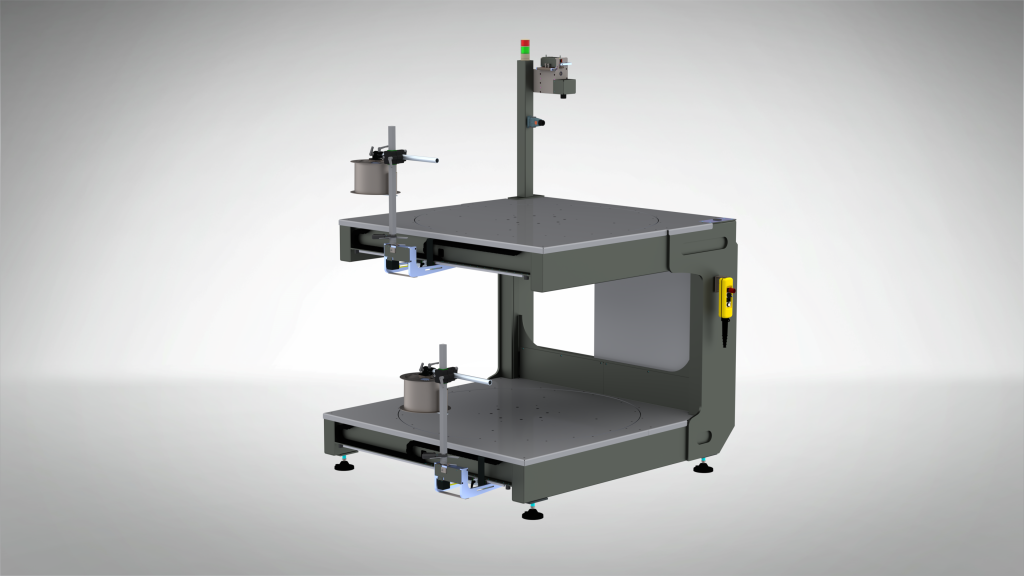

Our Horizontal Decoiler Type EH-1500 is a prime example of our standard offerings, designed to meet the rigorous demands of industrial production. Key features include:

- High Load Capacity: Supports reels with a load capacity of up to 3000 kg per reel, handling substantial material quantities directly from pallets.

- Optimized Feeding: Equipped with adjustable belt speeds (up to 9 m/min) and pneumatic dancer regulation, it precisely balances varying reel-off and draw-off speeds for continuous, smooth material flow.

- Robust Construction: Engineered for durability and high load capacity, ensuring reliable operation even in demanding environments.

- Advanced Features: Includes strap tension control, strap end detection, and an adjustable idler pulley for seamless operation and minimal material waste.

For more applications demanding dual reels for smooth and uninterrupted operations, we have developed the Double Horizontal Reel Decoiler DH-1500. The system supports dual reels with a load capacity of up to 2000 kg each and adjustable strap speeds, ensuring compatibility with a variety of production setups. Its advanced tension control, end-of-strap detection, and pneumatically controlled dancer regulation

Completing the range are the vertical decoilers in different configurations to support your varying decoiling requirements.

While these are powerful standard solutions, our strength also lies in our ability to adapt and integrate. We don’t just provide standalone machines; we seamlessly integrate them into your overall automation strategy, or even design completely custom feeding systems when your unique production requirements call for it. This holistic approach ensures that your material feeding is optimized within any automated or semi-automated manufacturing application.

The Benefits for Your Business

By implementing advanced decoiling and coiled material feeding solutions from VIAL Automation, you can achieve:

- Increased Productivity: Continuous, consistent material flow leads to higher output.

- Reduced Waste: Minimized material damage and precise feeding cut down on scrap.

- Lower Operational Costs: Automation reduces labor needs and prevents costly downtime.

- Enhanced Safety: Automated systems remove operators from potentially hazardous manual handling tasks.

- Improved Product Quality: Consistent material presentation leads to more uniform finished products.

Is your production line struggling with coiled materials?

Optimizing the start of your manufacturing process can have a ripple effect throughout your entire operation. At VIAL Automation, we are your trusted partner in developing and integrating solutions that ensure smooth, efficient, and reliable handling of your raw materials.

What challenges do you face when working with coiled materials? Share your thoughts in the comments!

#Decoiler #CoiledMaterial #MaterialHandling #Automation #ManufacturingEfficiency #IndustrialAutomation #MachineBuilding #SystemIntegration #VIALAutomation #ProductionOptimization #IndustrySolutions

We are here for you!

Ready to explore new opportunities? Contact us today to discuss your project requirements. Together, we can achieve precision, efficiency, and reliability in your manufacturing processes.

Follow us on social media: